As 3D printing is becoming more prevalent within the FPV and RC/UAV hobby I'd like to do a weekly "tuning tips" post so everyone can get their prints looking good and functioning well. I've been 3D printing since the early days of RepRap and the original Mendel and Huxley kits and have witnessed the hobby evolve massively over the years.

In todays thread we will be discussing stringing and what you can do to help prevent it and what slicer settings you should take a look at.

TL:DR...

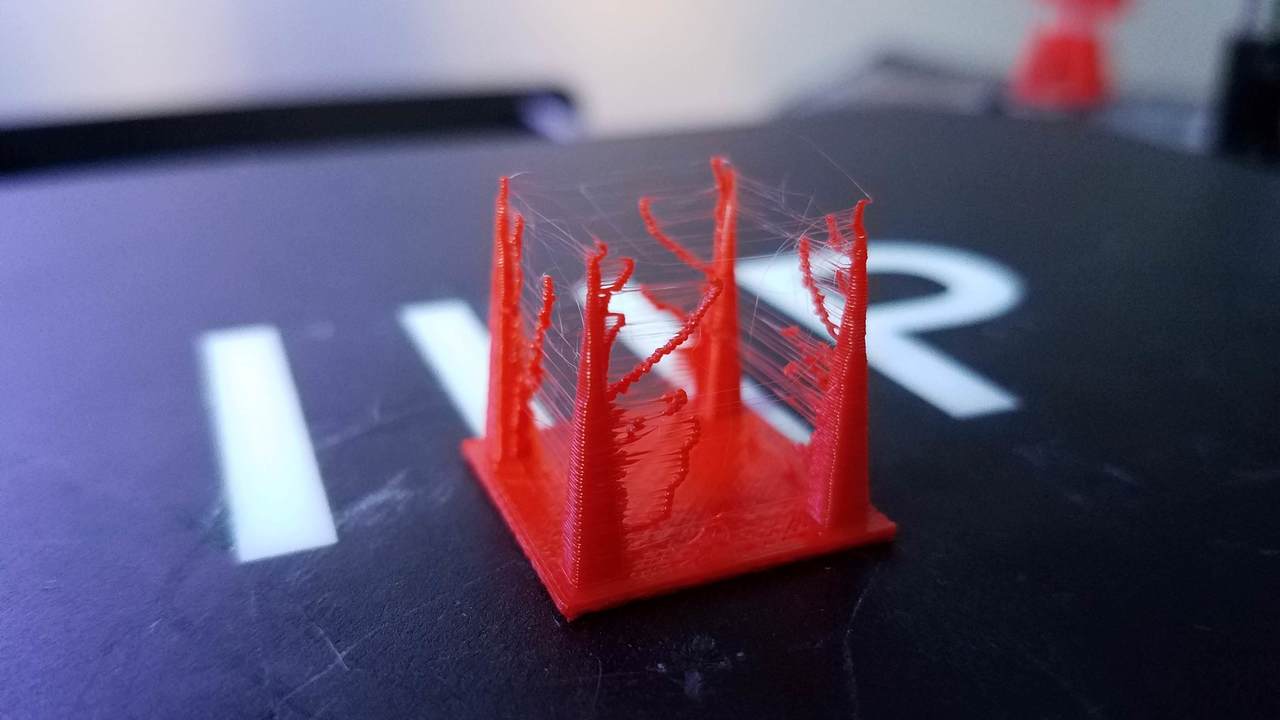

First, not all stringing is equal. Some strings are very wispy with no bumps on the part, and some are thicker and build on each other as the layers progress and can leave defects in the surface finish.

These are an example of thicker, more severe strings. This is usually caused by too low of retraction, too high of print temperature, no "wipe after retract", or no Combing (Cura). The plastic in the nozzle is not evacuated well, and or is too hot and so excess filament oozes and melts out of the nozzle as the print head travels. Increasing retraction can help, as can increasing retraction speed. Lowering print temp can also help but be very cautious and test layer adhesion and monitor top layer quality and perimeter quality to ensure you do not have underextrusion. Increased cooling can also help, but should be a secondary setting change and should be considered after major stringing is solved. Some slicers have settings to change the travel moves of the print to avoid crossing external perimeters and this can be used however it often comes at the expense of print time and odd surface defects. Thick strings and blobs can also be a sign of wet or water-logged filament and so drying should be considered. Especially with Nylon and PETG, they produce thick strings and surface defects when wet.

However, be careful of how much you retract. For Direct Drive printers (Prusa i3 MK3, Sovol SV01, Maker Select V2/ Wanhao i3) you need to understand how long the "throat" on your printer is, or what the distance between the extruder gears and nozzle. A general rule of thumb is do not go beyond 1.5 to 2mm of retraction. For Bowden style printers (Ender 3, Prusa Mini, CR10) you might need 2, 3 even 4mm of retraction to make a difference. As it is a bowden style there is a large distance between the nozzle and the extruder gear so the effects of retraction are much slower, and you often have to retract the filament out of the heatbreak completely to avoid oozing.

This is an example of thin, wispy strings. Contrary to above, these thin strings can be solved with a higher print temperature, more print cooling, faster travel speed, or drying the filament. TPU when wet produces these very thin wispy strings that are hard to solve with slicer setting tuning. However these strings are very easy to solve in post-processing as you can use a lighter, hair dryer or torch to "melt" and shrink the strings into the surface.

As mentioned above too much retraction may be an issue. Retracting too much can lead to extrusion issues and surface defects where the line start is underextruded, or you get blobs or bubbles close to the line start where the filament suddenly comes out of the nozzle.

If you look at the base of the cabin on this benchy, and that odd line on the hull, these are artifacts from excess retraction. This is my benchy a few months ago, a Wanhao i3 with an E3D Titan Aero hotend. My retraction was 1.5mm, and as the printer started the next line after retract the filament wasn't filling the nozzle fast enough leading to gaps at the line start, and then blobs as the filament floods the nozzle during printing. You want enough retraction to minimize strings but not so much you get retraction artifacts and perimeter issues.

Happy printing!

Looking forward to your next post

Great post! Thank you for sharing

Awesome post!! these are the kind of posts that will earn you badges! Thank you so much for contributing!